Elite Finishing Systems

It all started with one singular paint booth system that set the tone for our entire company and our commitment to high quality.

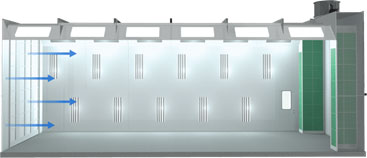

Crossdraft Airflow Designs

Air movement through a crossdraft booth

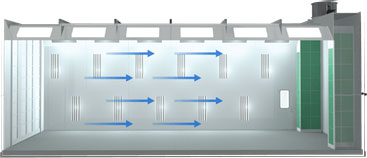

Air movement through a crossdraft booth

Airflow designs are a defining element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Airflow systems impact every aspect of a booth’s operation, so companies should carefully weigh how their chosen design will affect operating costs, quality of results and workplace safety.

Recommended for:

All Industries + Basic Finishing Requirements

• Cost-Efficient Performance

• Minimal Installation Requirements

• Simple Maintenance and Upkeep

The standard in airflow designs, a crossdraft spray booth can be designed to handle a wide variety of uses and is typically recommended for parts that require a basic finishing quality and application process. The minimal installation requirements needed for this style of airflow design make it an ideal solution for most finishing facilities. The term crossdraft refers to how the air travels through the booth: horizontally along the “cross-section” of the booth.